Complete solutions - One supplier

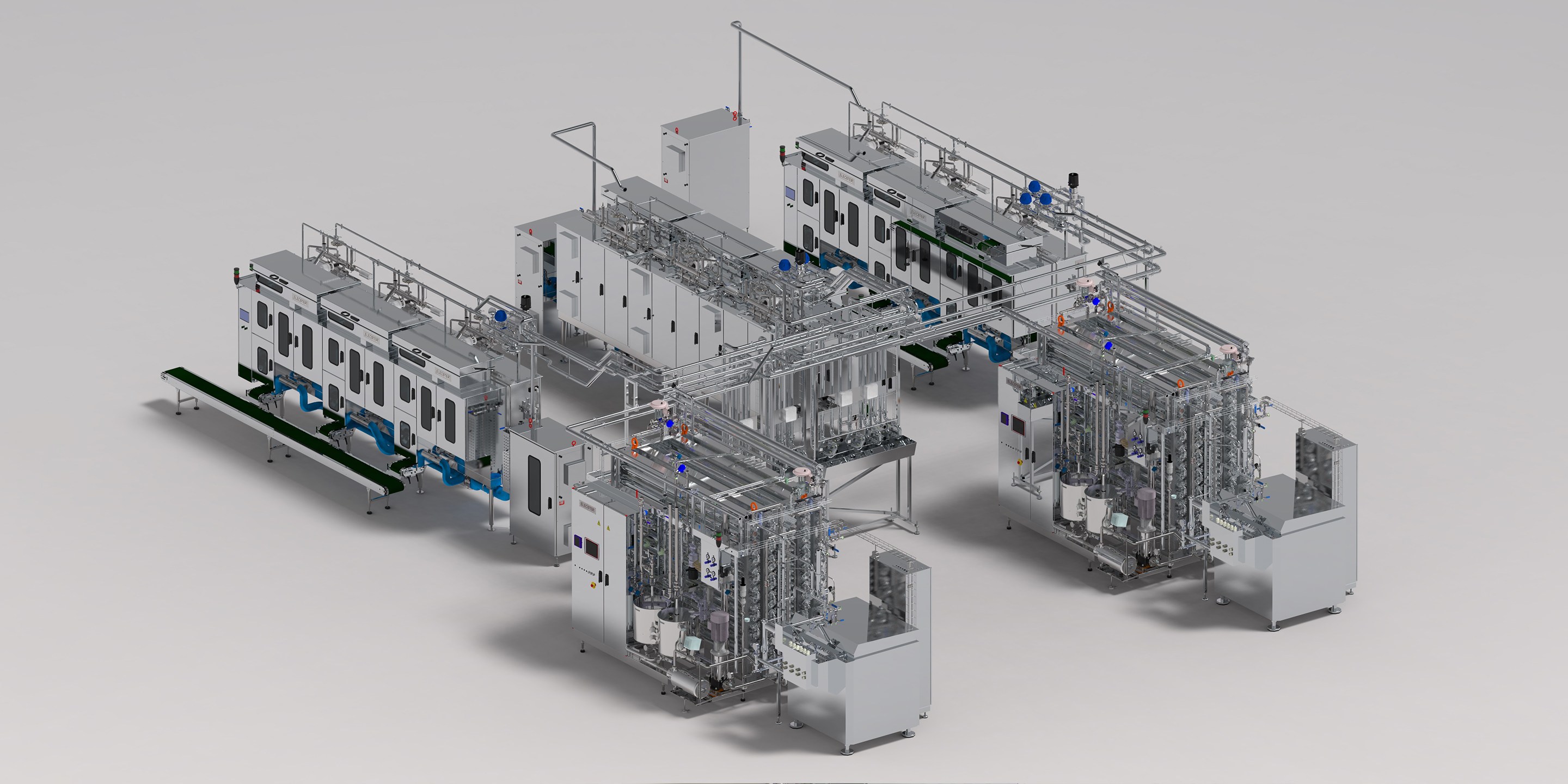

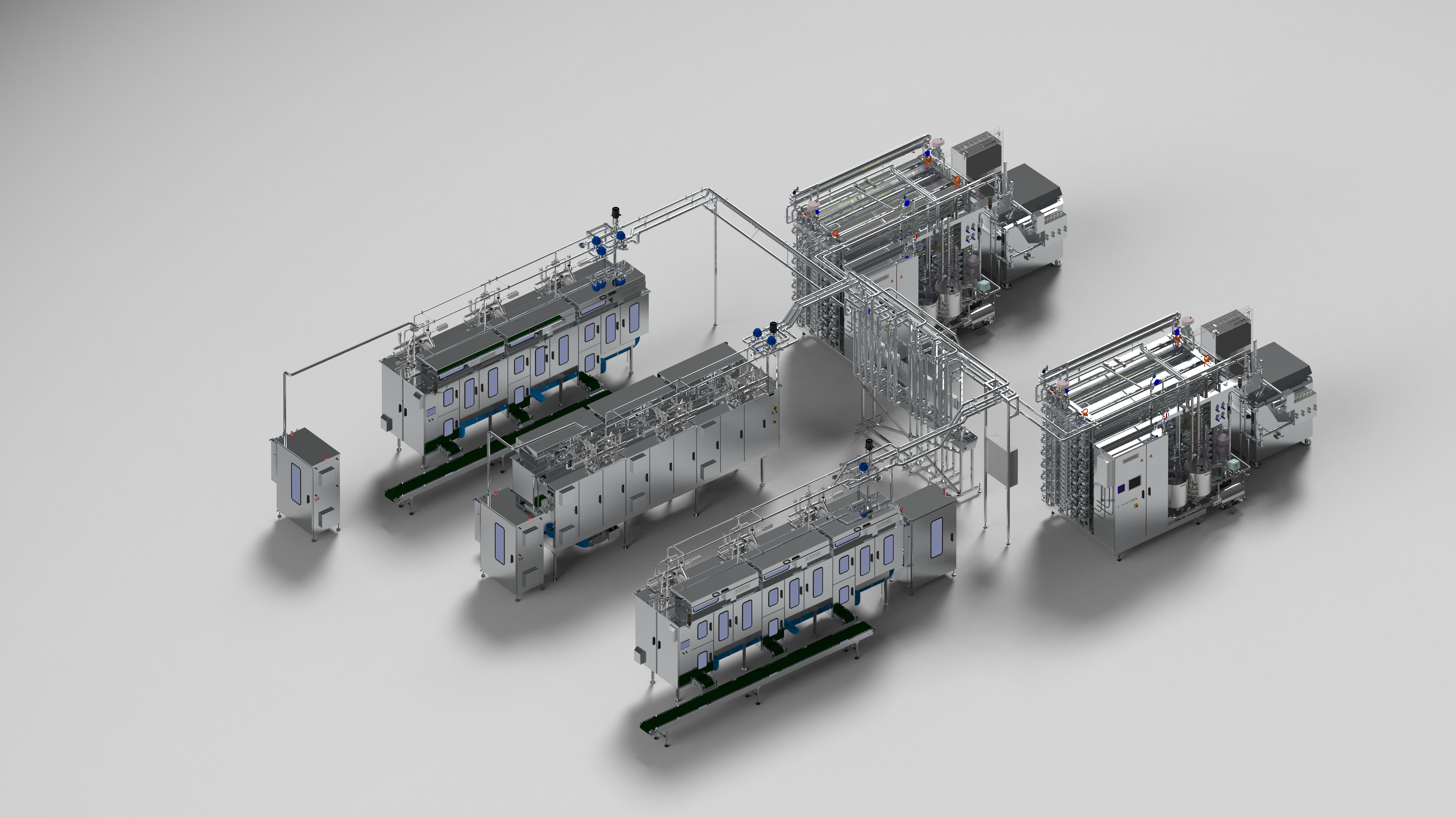

Elecster offers a turnkey solution for UHT milk processing and packaging. Thanks to a wide range of capacity options, we are able to customize the right size UHT line according to the customer’s requirements, starting from 800 liters per hour up to 10,000 liters per hour. If the need for capacity is even greater, Elecster UHT lines can be integrated with each other. This means that the capacity of Elecster UHT lines is expandable and therefore it is almost limitless. This advantage allows you to start UHT milk production at just the capacity you want. Thanks to the integration option, you can easily add more processing capacity or packaging capacity to your existing UHT line, without having to upgrade the entire equipment. The Elecster solution is suitable for both beginners and those already in the field.

As a turn-key solution supplier, Elecster provides complete UHT milk processing and packaging lines, packaging material, downstream equipment and aftersales services.

Our technology means reliability and responsibility.

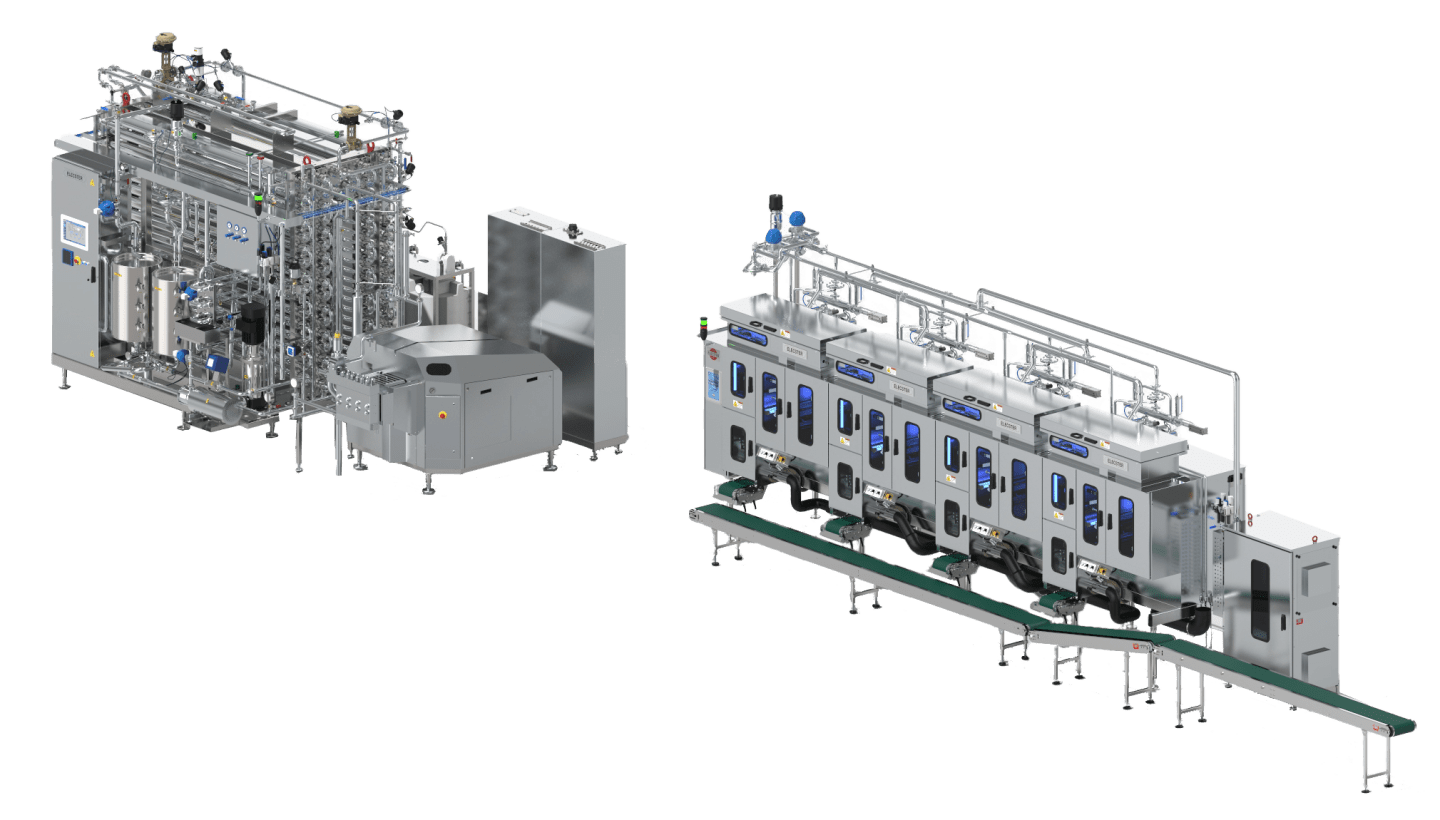

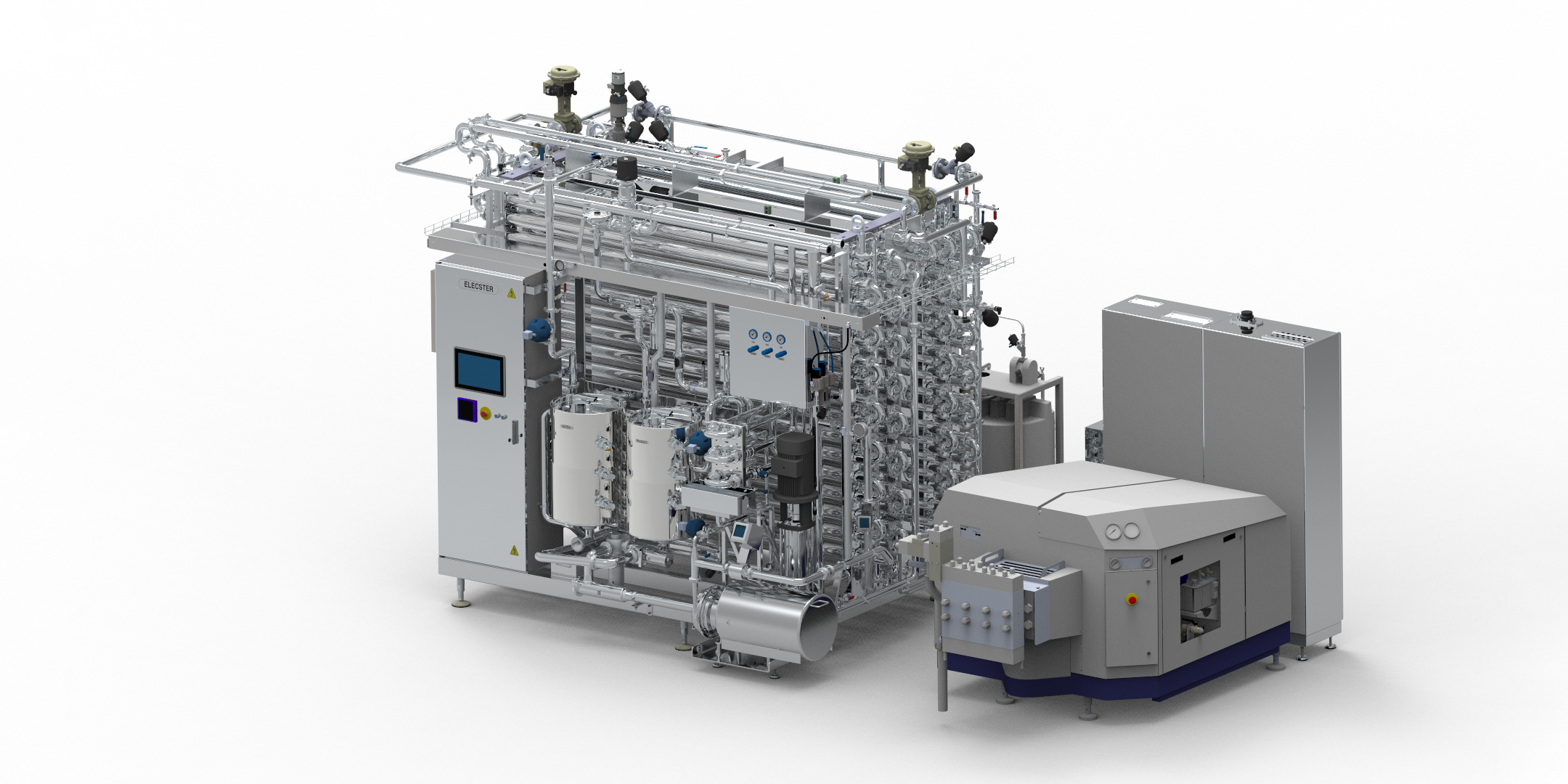

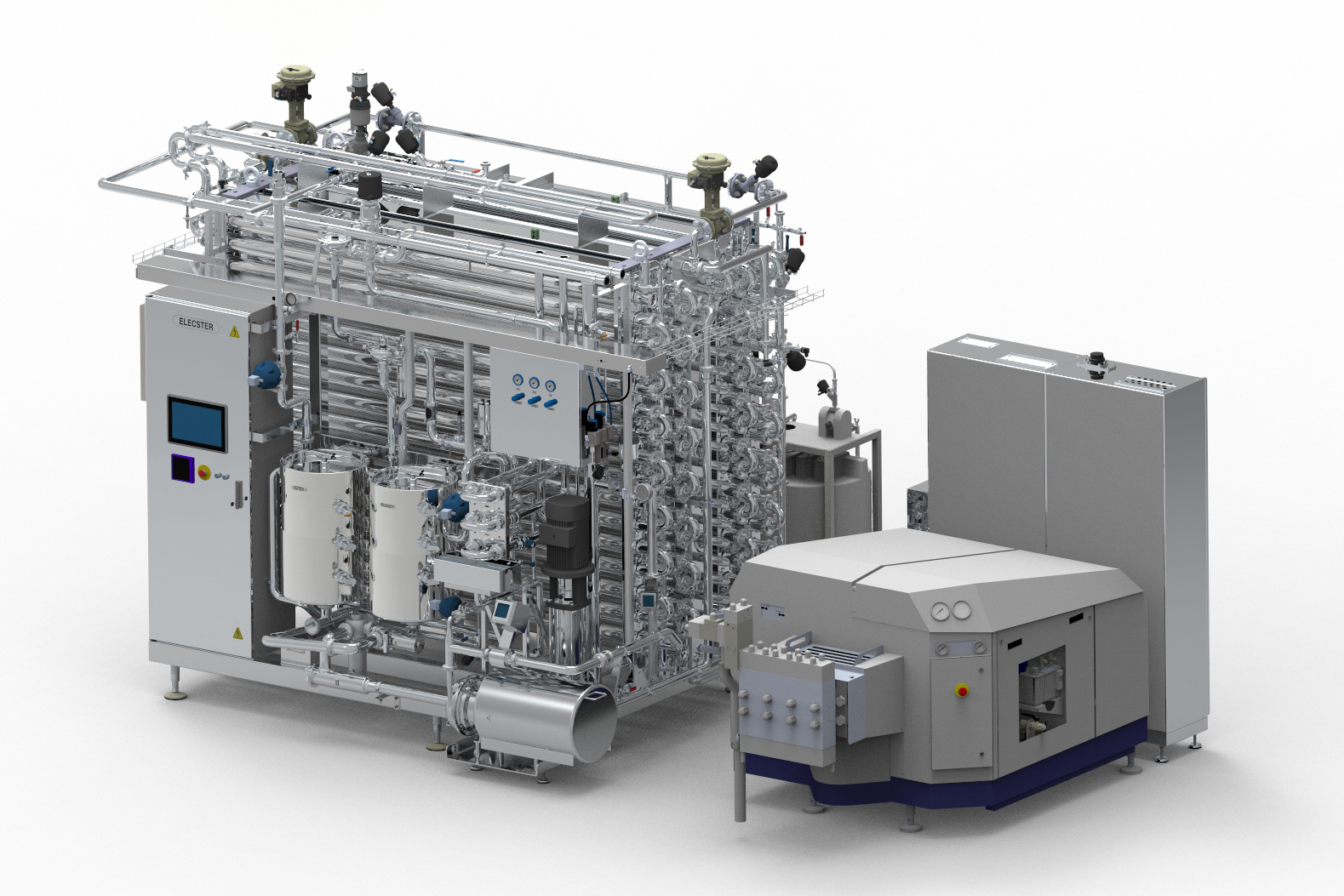

Compact system with optimized capacities. Elecster processing and packaging machines are tailored to work as a complete line. This is a guarantee for high performance and production efficiency. No need for expensive aseptic buffer tank or separate CIP system, which makes Elecster complete UHT line a cost efficient and space saving solution.

Elecster equipment is designed, assembled and tested in Finland. Test runs are performed on the entire UHT line at the Elecster factory. For this reason, the installation and commissioning of the line is effortless and fast.

Elecster complete UHT line output capacity is from 800 liters per hour up to 10000 liters per hour.

Comprehensive support and deep understanding of complete UHT line is a guarantee for smooth production. In case of any problems with the equipment, you deal only with one supplier. Supplier, who knows its own equipment and is able to provide services and spare parts in short time without questioning liability.

Click To Enlarge Images

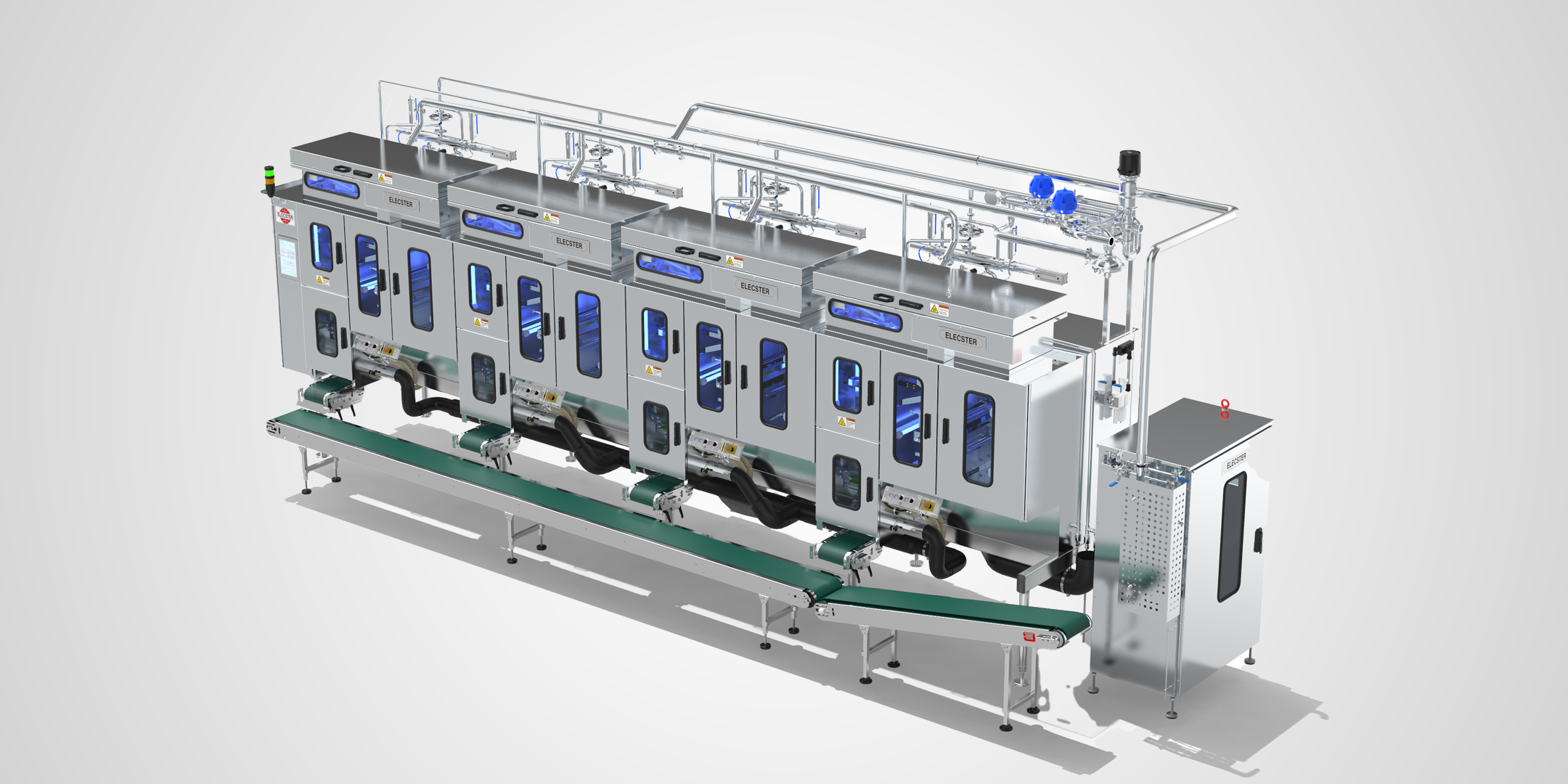

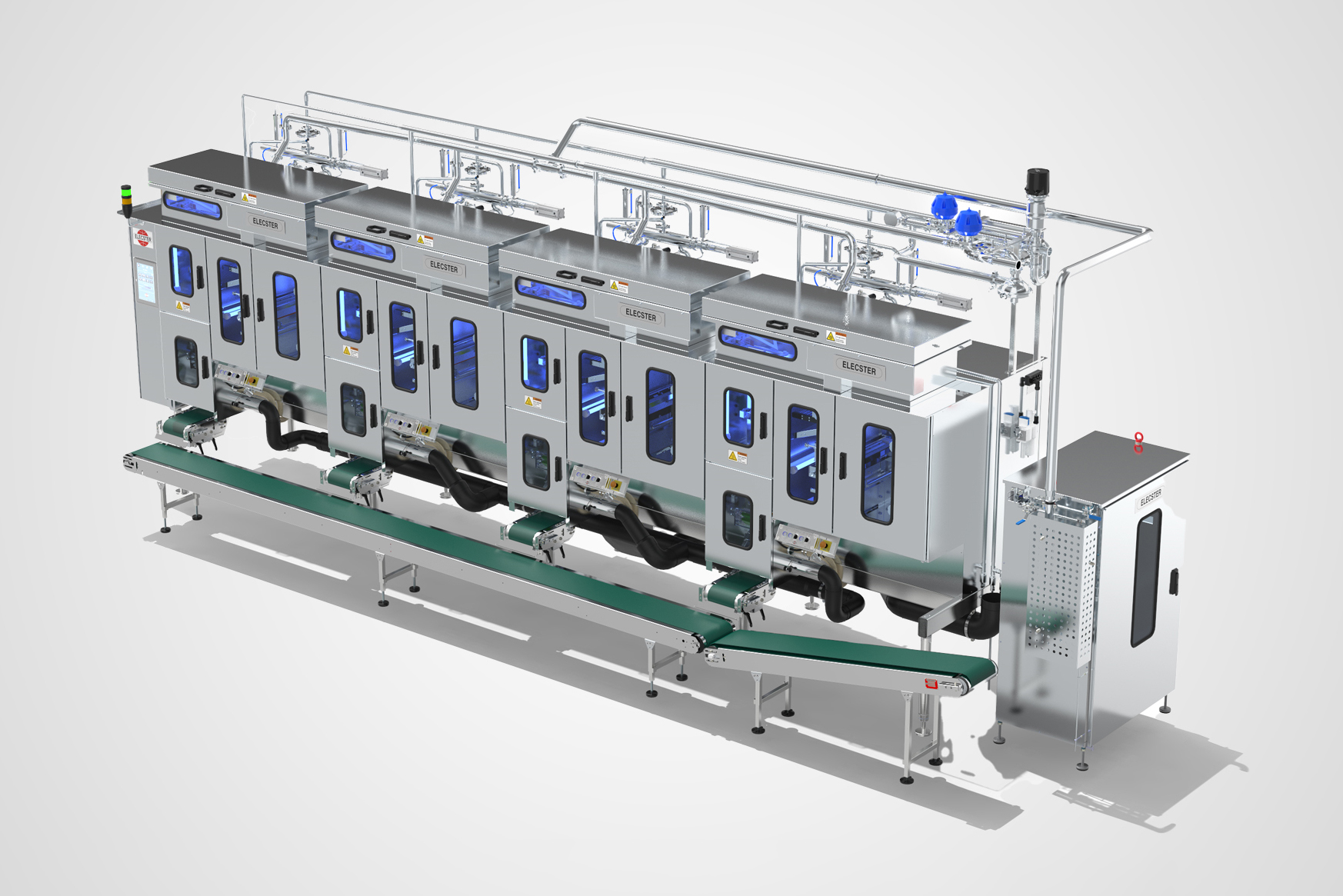

Thanks to its modular structure and adjustable volume, Elecster is always able to offer suitable capacity option according to the customer's needs. Capacity up to 16000 pcs/h and 100 ml - 1300 ml pouch sizes available. The packaging machine has one to four packing heads, depending on the capacity requirement. Maximum capacity of one packaging head is 4000 pcs/h.

Reliable and lasting seams are guaranteed by permanently heated sealing devices. The temperature of the heat sealing is adjusted with an accurate PID control. The film is sealed inner surface against inner surface. The form of the package is pillow pouch.

Elecster technology enables to get high quality pouch, vanishing leakage problems and outstanding image printing. Volume based dosing unit is a guarantee for stable and accurate dosing. Automatic film track control and sealing device temperature control ensure minimal packaging material loss.

The metering device and the tubing are sterilized by hot water (>121°C). The integrated air sterilizer equipment maintains the aseptic conditions in the sterile chamber and the packaging film tube. The packaging film is sterilized with H2O2 and with powerful UV radiation.

You can optimize your production and gain profitability by using Elecster filling machines with Elecster packaging material, which are developed hand in hand. High aseptical level of packaging machine together with Elecster high quality packaging material enables to reach long product shelf-life from 90 days up to 180 days.

Click To Enlarge Images

For more detailed information, please contact us!

CONTACT US

Long experience, deep knowledge, high quality components and materials assures the Elecster sterilizer’s high product quality and food safety. Sterilizer’s construction is stainless steel and complete system includes homogenizer and CIP unit.

The capacity and the process temperature of the sterilizer can easily be adjusted to fit different capacities and products. Products like pasteurized milk, powdered milk, flavored milk, low fat cream and drinking yoghurt.

Sterilizer has low utility consumption and the heat regeneration level is approx. 90%. Steam is used as the heating energy source.

The sterilizing temperature is measured by double detector system and controlled by a two-level low temperature alarm. The alarm system shows the possible operation fault through the monitor. The tubular heat exchangers are protected by a security system which informs about the need of intermediate cleaning. An automatic CIP/AIC system is integrated to the equipment.

The sterilizer is equipped with a remote access control that allows online support. This feature ensures possibility for immediate support and troubleshooting. Sterilizer process data can be stored automatically. Process data can be read with PC or mobile device.

Click To Enlarge Images

For more detailed information, please contact us!

CONTACT US

Easy, fast and money saving solution for those who are planning to expand the production capacity. Add another packaging machine to the existing sterilizer or connect another complete UHT line to the existing UHT line.

Elecster Integration System, EIS through its cross-connection panels and ECB signalization box enables to optimize the utilization of sterilizer(s) capacities with several aseptic filling machines/packaging sizes and thus saving investment in expensive aseptic buffer tank.

Sterilizer does not have to be tied to a one specific packaging machine. Sterilizer is able to feed several packaging machines at the same time or separately. By switching the connection between sterilizer and packaging machines you can keep your production running around the clock.