ELECSTER

Complete solutions - One supplier

Elecster is the leading company in the world as a system supplier for UHT lines, Aseptic Pouch Filling Machines and ecological Pouch Packaging Materials. With over 50 years’ experience of engineering and manufacturing of dairy machinery and packaging material it has developed the superior know-how of compatibility required for milk pouch technology.

PRODUCTS

Make Your Success Story

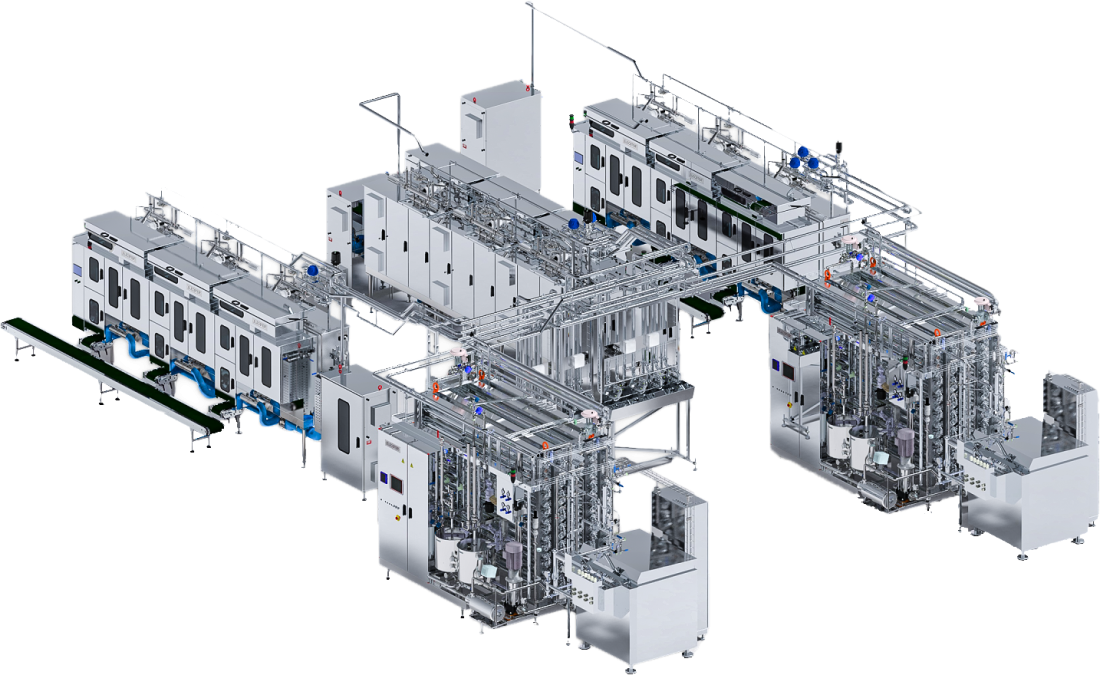

Elecster offers a turnkey solution for UHT milk processing and packaging. Thanks to a wide range of capacity options, we are able to customize the right size UHT line according to the customer’s requirements, starting from 800 liters per hour up to 10,000 liters per hour. If the need for capacity is even greater, Elecster UHT lines can be integrated with each other. This means that the capacity of Elecster UHT lines is expandable and therefore it is almost limitless. This advantage allows you to start UHT milk production at just the capacity you want. Thanks to the integration option, you can easily add more processing capacity or packaging capacity to your existing UHT line, without having to upgrade the entire equipment. The Elecster solution is suitable for both beginners and those already in the field.

As a turn-key solution supplier, Elecster provides complete UHT milk processing and packaging lines, packaging material, downstream equipment and aftersales services.

Our technology means reliability and responsibility.

ELECSTER

All products

Elecster offers a turnkey solution for UHT milk processing and packaging. Thanks to a wide range of capacity options, we are able to customize the right size UHT line according to the customer’s requirements, starting from 800 liters per hour up to 10,000 liters per hour.

PRODUCTS

Advanced Solutions for UHT Processing & Packaging

Elecster stands as a global leader in providing comprehensive solutions for UHT processing lines, aseptic pouch filling machines, and eco-friendly pouch packaging materials. With over five decades of experience in engineering and manufacturing dairy machinery and packaging materials, Elecster has developed unparalleled expertise in milk pouch technology.

Complete UHT Lines

Elecster offers turnkey solutions for UHT milk processing and packaging, with capacities ranging from 800 to 10,000 liters per hour. For higher demands, these lines can be integrated to expand capacity seamlessly. This flexibility allows dairies to start at a suitable scale and grow as needed, ensuring efficient and scalable operations.

Aseptic Pouch Packaging Machines

Designed with a modular structure and adjustable volumes, Elecster’s aseptic pouch machines cater to various capacity requirements, producing up to 16,000 pouches per hour in sizes ranging from 100 to 1,300 ml. The machines utilize permanently heated sealing devices to ensure reliable and durable seams, while volume-based dosing units guarantee accurate filling. Advanced sterilization methods, including H₂O₂ treatment and UV radiation, maintain high aseptic levels, enabling product shelf lives of up to 180 days.

Pasteurized Pouch Packaging Machines

For pasteurized milk products, Elecster provides packaging machines like the FP-2500 and FP-5000, with capacities of 2,500 and 5,000 pouches per hour, respectively. These PLC-controlled machines offer easy operation, allowing users to set startup parameters for different products and package sizes. The machines accommodate pouch sizes from 200 ml to 1,000 ml, with straightforward adjustments for size changes. Manufactured in Finland, they meet stringent European safety standards, ensuring both efficiency and safety in dairy operations.

Ecological Pouch Packaging Materials

Elecster has developed multilayer packaging materials in tandem with its machinery, optimizing properties for superior performance. These materials offer excellent sealing capabilities, preventing leaks even at high packaging speeds. Depending on shelf-life requirements, Elecster provides both PE-multilayer materials for up to 30 days and long-life materials with outstanding oxygen barrier properties for shelf lives extending to six months. Utilizing Expanded Gamut Printing (EGP) technology, Elecster achieves high-quality, full-HD printing while reducing environmental impact through lower ink and solvent usage. Notably, Elecster’s packaging materials are 100% recyclable, underscoring the company’s commitment to sustainability.

After-Sales Services

Beyond product offerings, Elecster provides comprehensive after-sales services, including technical support, maintenance, and training, ensuring that clients maximize the value and efficiency of their investments. This commitment to customer success reinforces Elecster’s position as a trusted partner in the dairy industry.

In summary, Elecster’s extensive range of products and services reflects its dedication to innovation, quality, and environmental responsibility, providing dairies worldwide with reliable and efficient solutions for milk processing and packaging.