ELECSTER

Sterilizers

Elecster is the leading company in the world as a system supplier for UHT lines, Aseptic Pouch Filling Machines and ecological Pouch Packaging Materials. With over 50 years’ experience of engineering and manufacturing of dairy machinery and packaging material it has developed the superior know-how of compatibility required for milk pouch technology.

ELECSTER

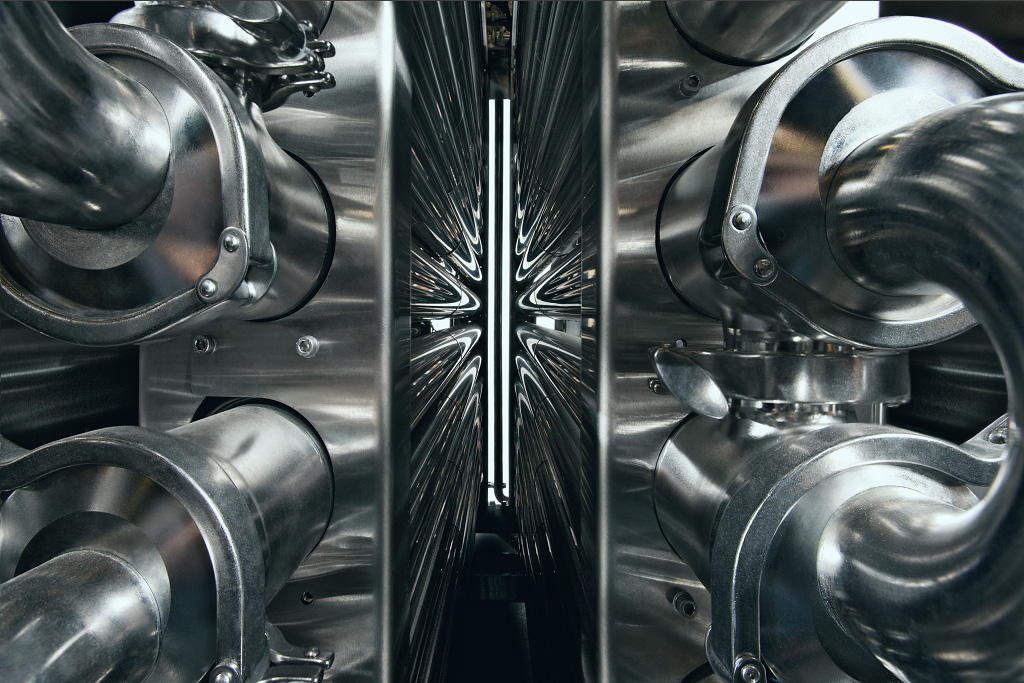

Reliable and secure processing

The sterilizing temperature is measured by double detector system and controlled by a two-level low temperature alarm. The alarm system shows the possible operation fault through the monitor. The tubular heat exchangers are protected by a security system which informs about the need of intermediate cleaning. An automatic CIP/AIC system is integrated to the equipment.

PRODUCTS

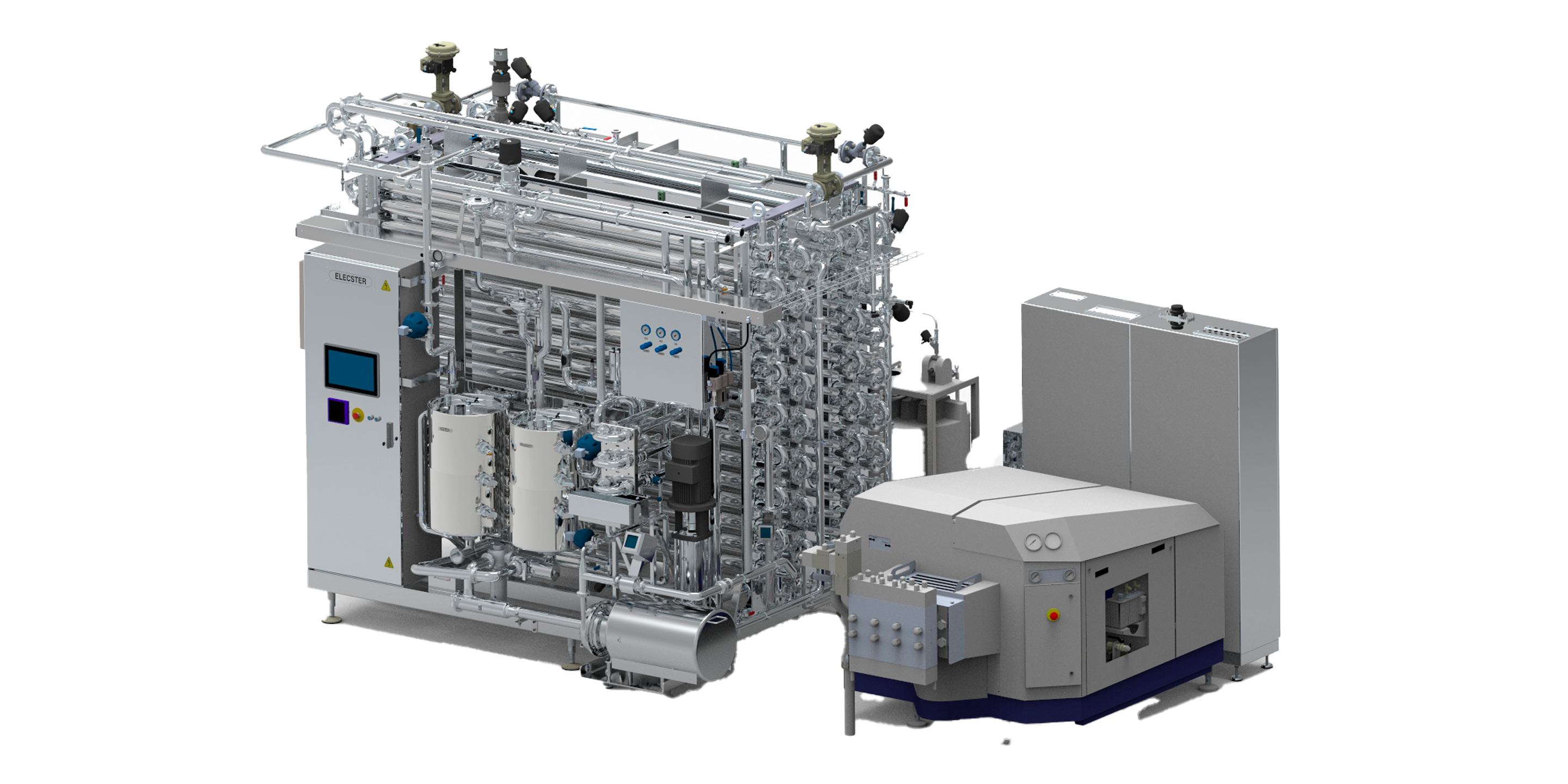

Online support and process data storage

The sterilizer is equipped with a remote access control that allows online support. This feature ensures possibility for immediate support and troubleshooting. Sterilizer process data can be stored automatically. Process data can be read with PC or mobile device.

Sterilizers specs

- Sterilizer

- Homogenizer

- Aseptic Packaging Machine

- Air Sterilizer

- Pouch conveyors and downstream equipment

- CIP/AIC washing equipment

Long experience, deep knowledge, high quality components and materials assures the Elecster sterilizer’s high product quality and food safety. Sterilizer’s construction is stainless steel and complete system includes homogenizer and CIP unit.

The capacity and the process temperature of the sterilizer can easily be adjusted to fit different capacities and products. Products like pasteurized milk, powdered milk, flavored milk, low fat cream and drinking yoghurt.

Sterilizer has low utility consumption and the heat regeneration level is approx. 90%. Steam is used as the heating energy source.

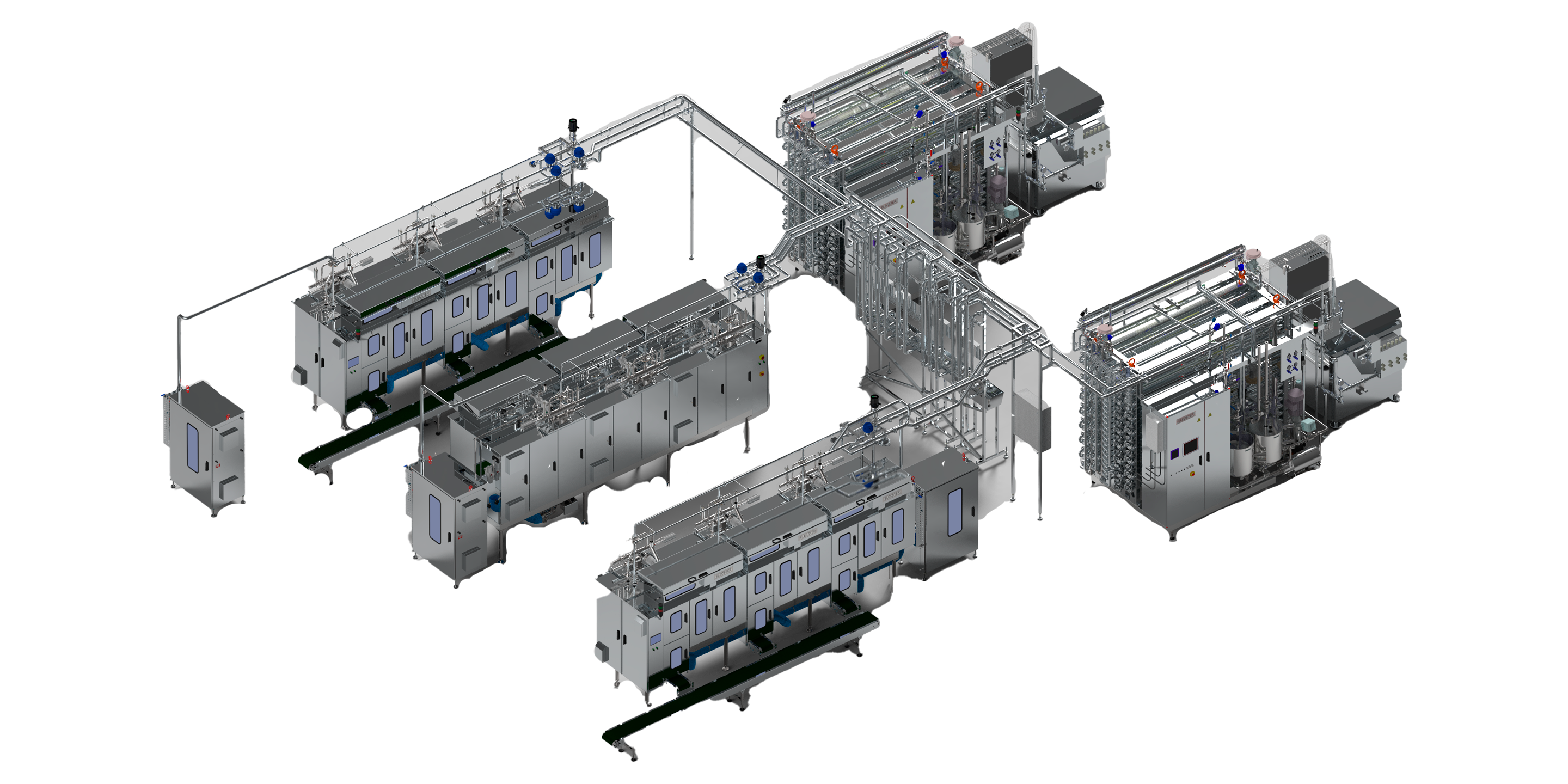

Easy, fast and money saving solution for those who are planning to expand the production capacity. Add another packaging machine to the existing sterilizer or connect another complete UHT line to the existing UHT line.

Flexibility

Elecster Integration System, EIS through its cross-connection panels and ECB signalization box enables to optimize the utilization of sterilizer(s) capacities with several aseptic filling machines/packaging sizes and thus saving investment in expensive aseptic buffer tank.

Sterilizer does not have to be tied to a one specific packaging machine. Sterilizer is able to feed several packaging machines at the same time or separately. By switching the connection between sterilizer and packaging machines you can keep your production running around the clock.